THE DfL ADVANTAGE

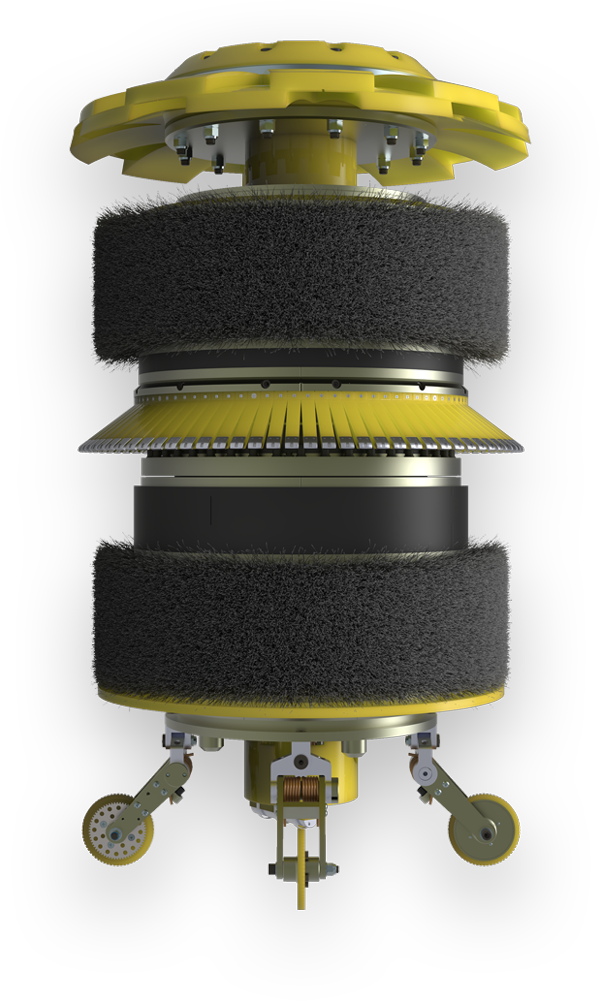

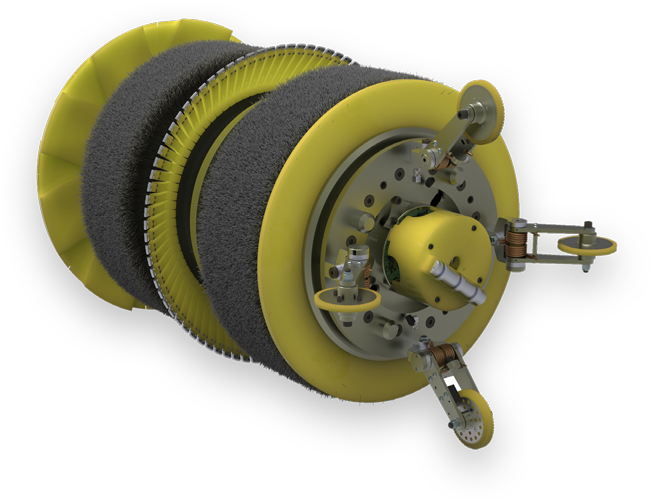

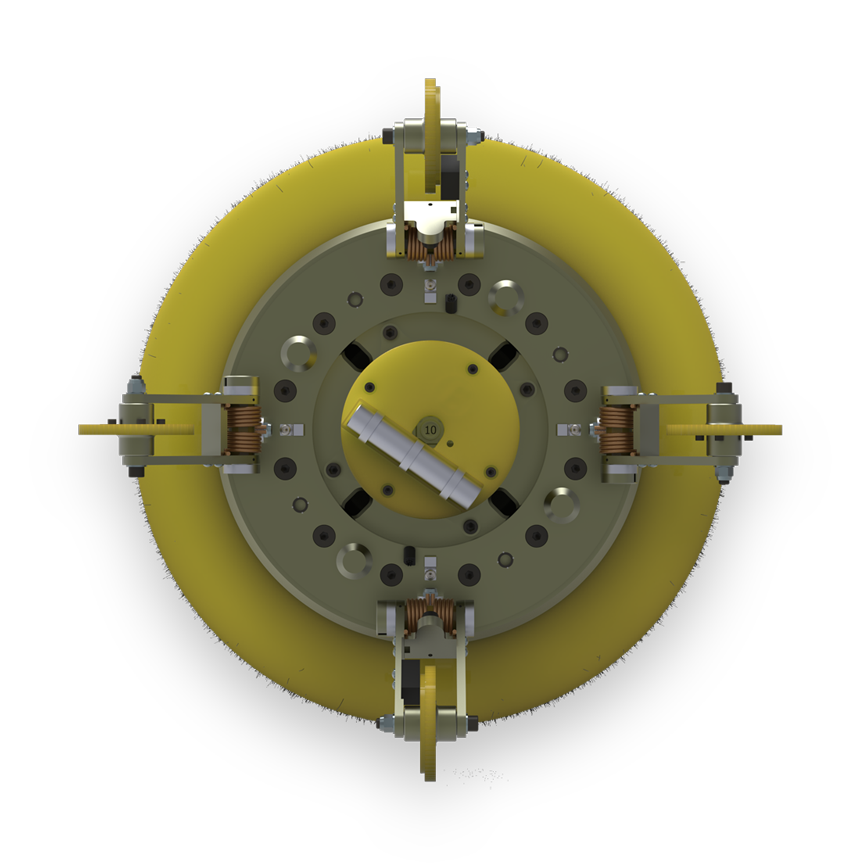

- Industry Leading Design

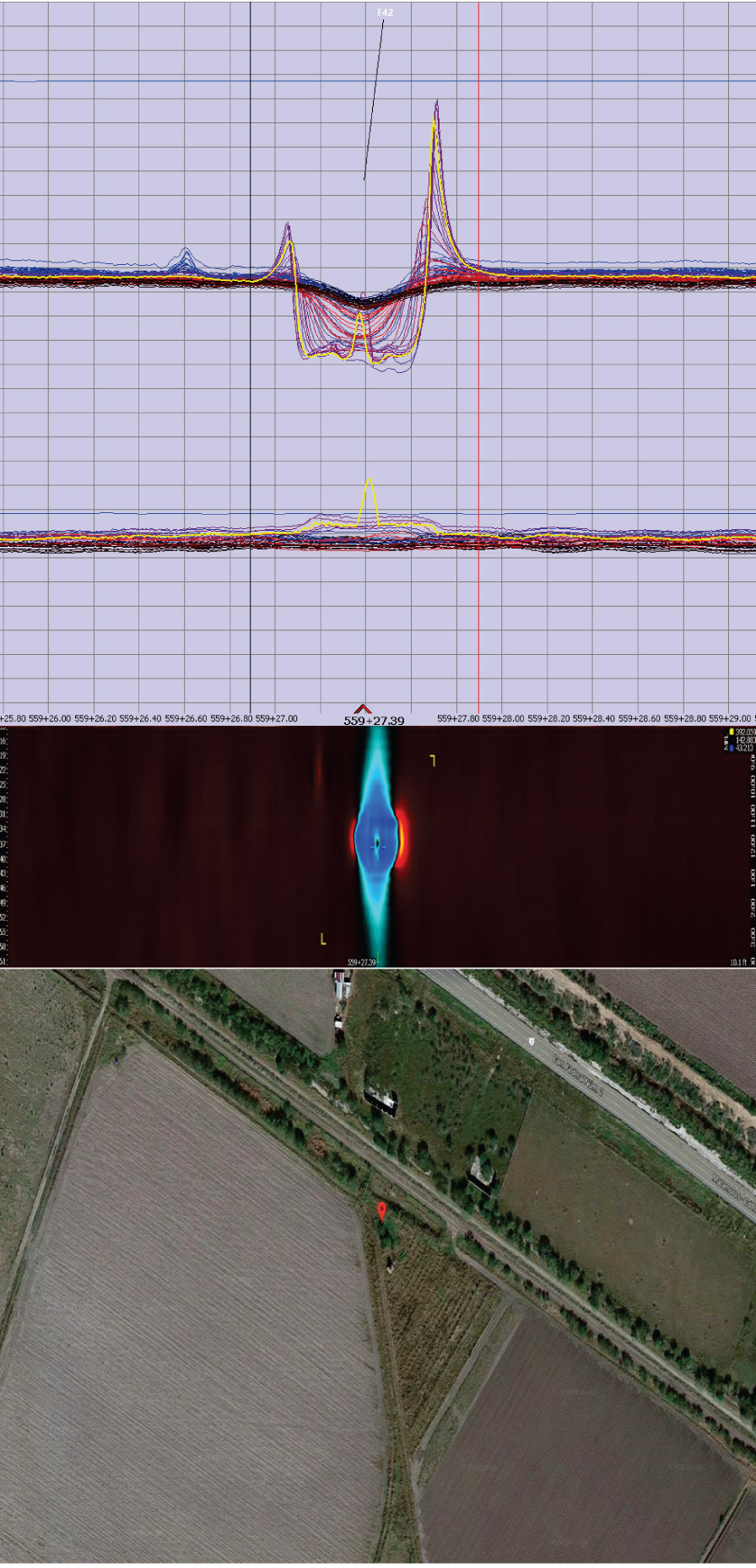

- Robust Data Collection

- GPS Excavation Points

- Single Pass

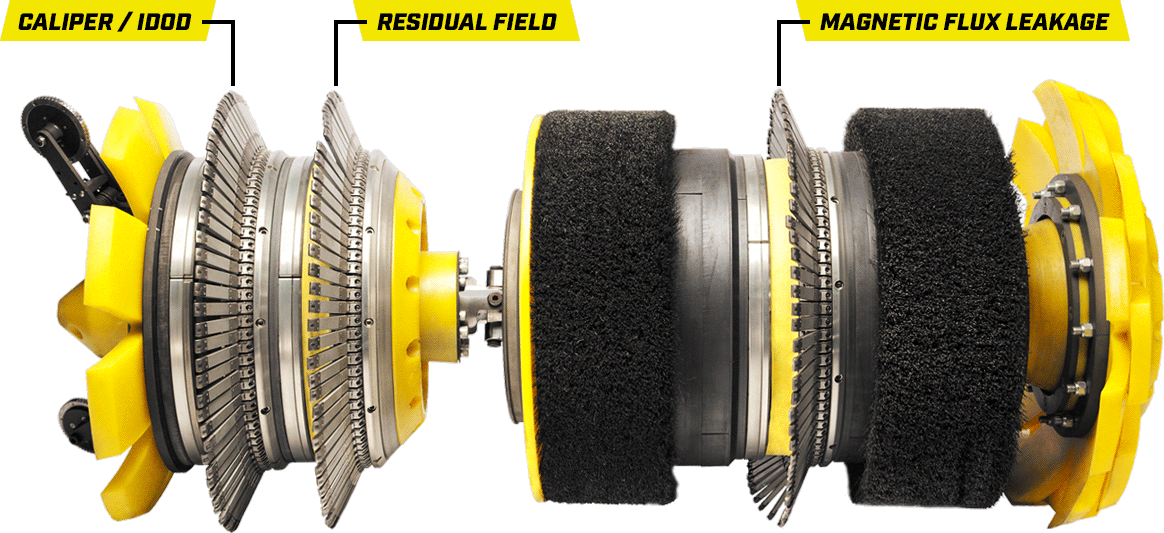

Data sets for conducting metal loss, deformation, and inertial surveys, along with internal/external discrimination and residual field data are taken in a single pass of the inspection tool. The DfL utilizes axial magnetic flux leakage data to provide an assessment of metal loss occurring within a pipeline.

Concurrent data set collection greatly simplifies the process of identifying features and anomaly types. Processing and analyzing the closely coupled data allows analysts to more readily recognize pipeline features and assess conditions. Any areas indicating geometry and/or metal loss features may now be simultaneously evaluated for deformation, strain, profile, and permeability variations.

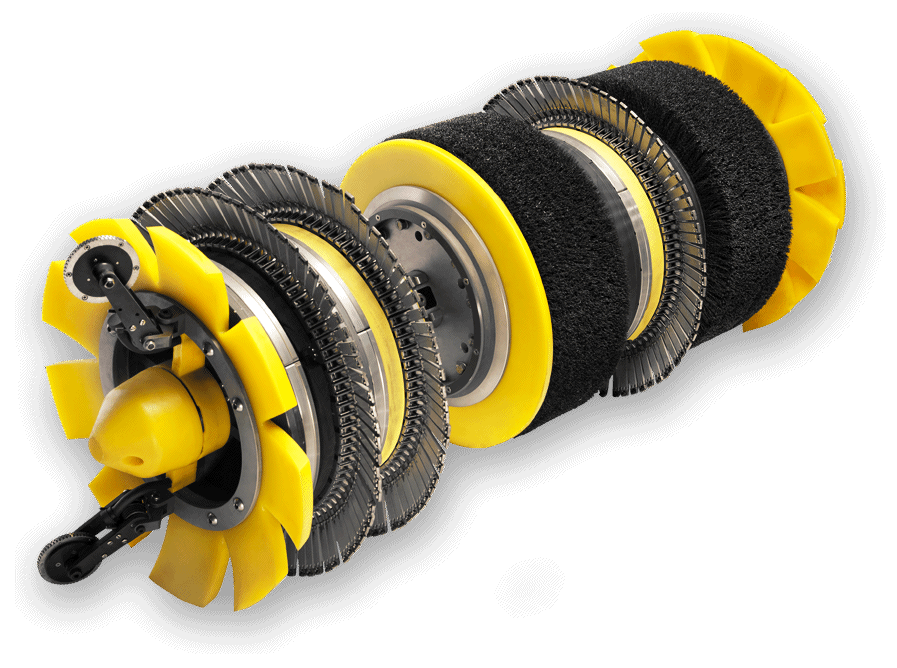

The tool utilizes some of the most advanced design, data storage and packaging techniques presently available, as evidenced by the diverse data sets being taken and limited physical size and weight of the tools themselves, typically less in length and weight than most presently being offered.