MFL-DFL

THE DfL-UHR ADVANTAGE

- Industry Leading Design

- Robust Data Collection

- GPS Excavation Points

- Single Pass

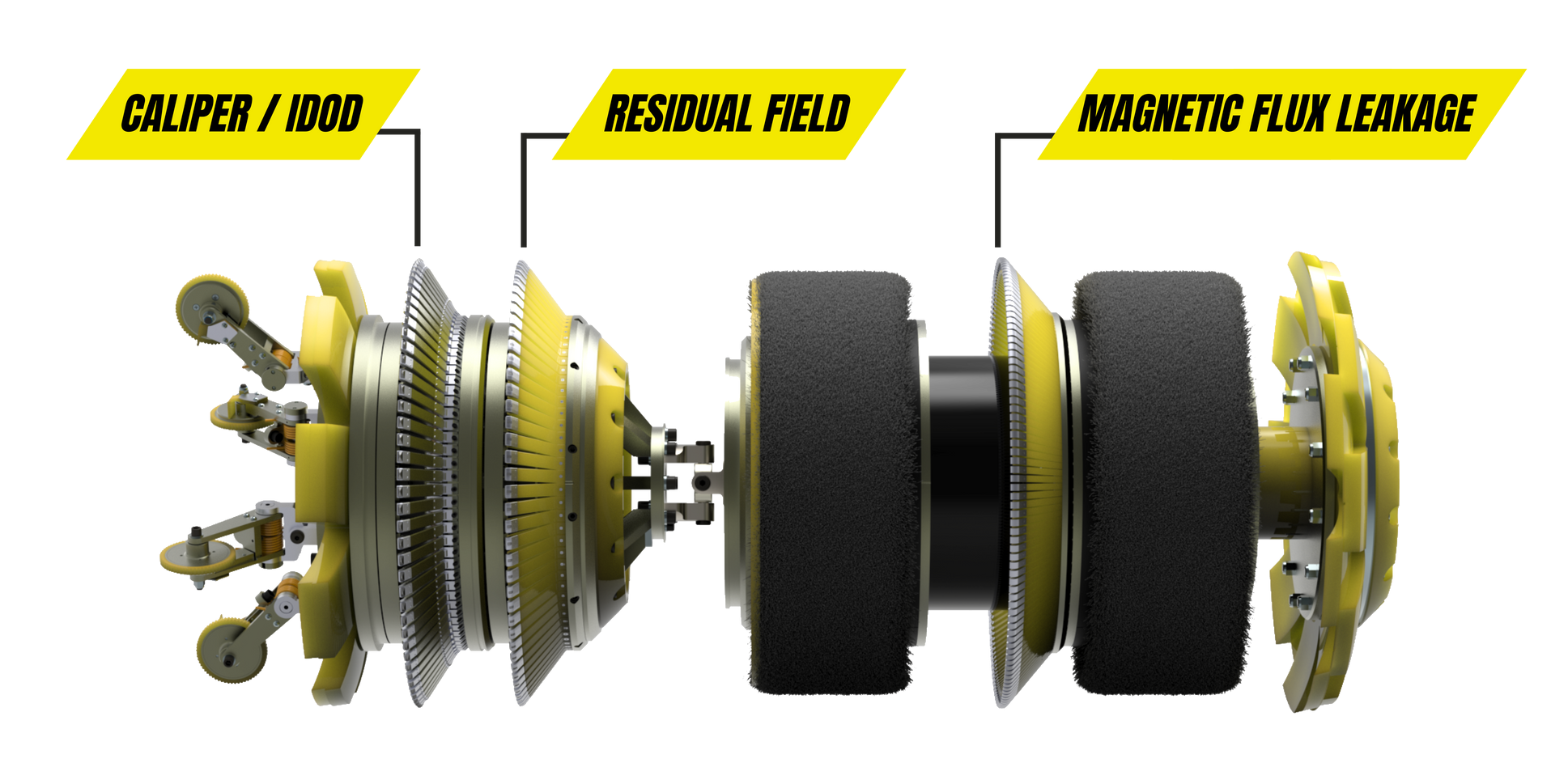

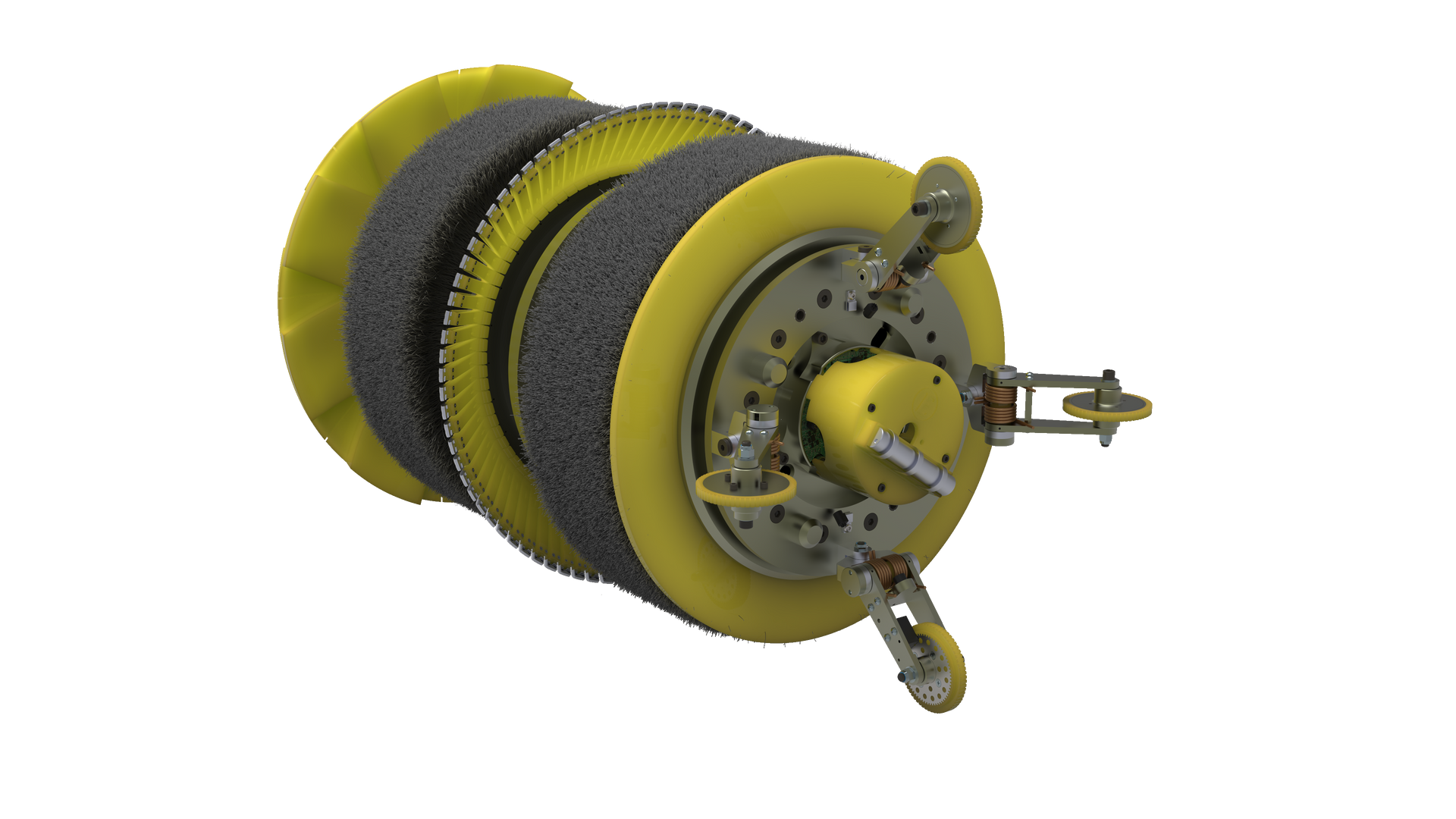

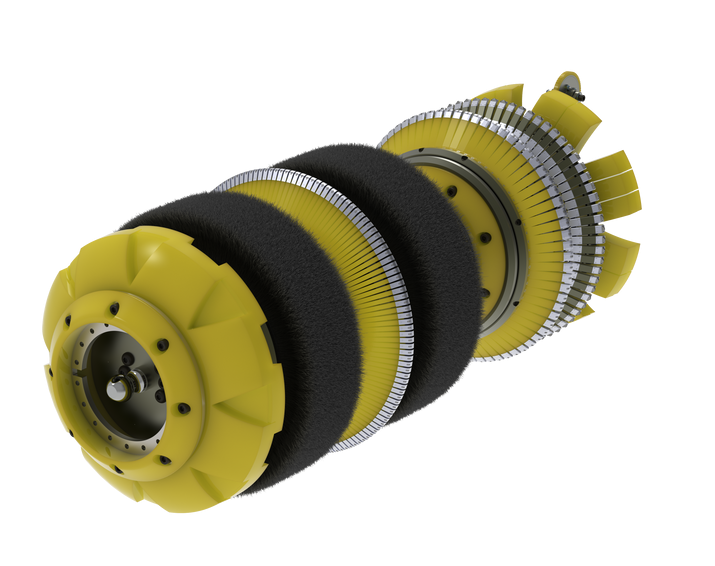

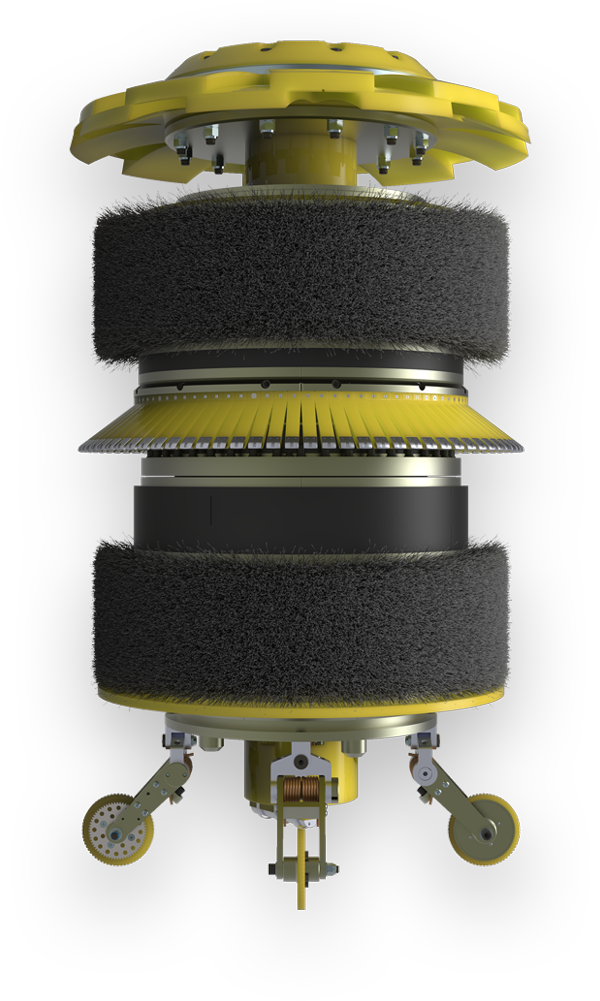

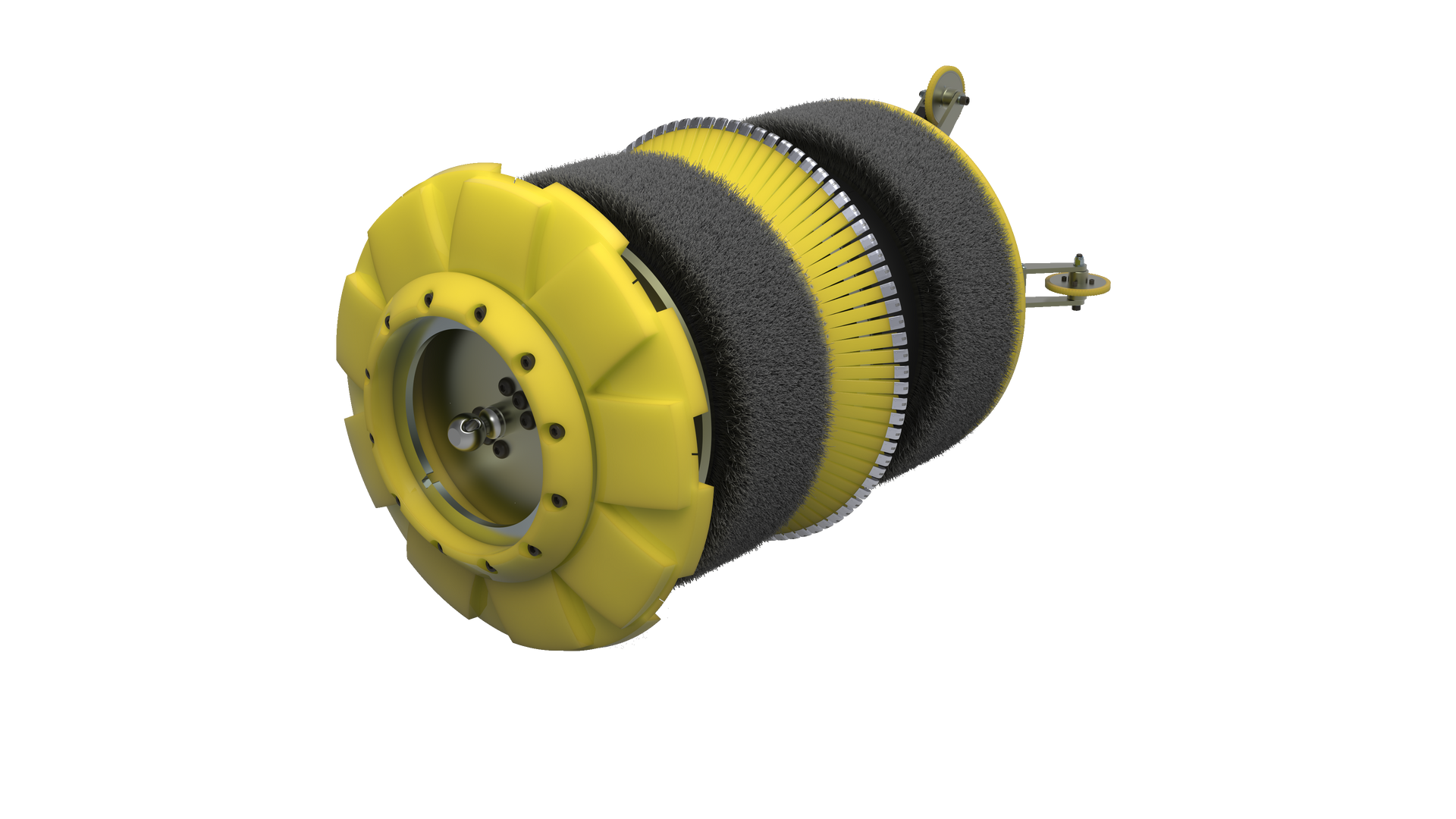

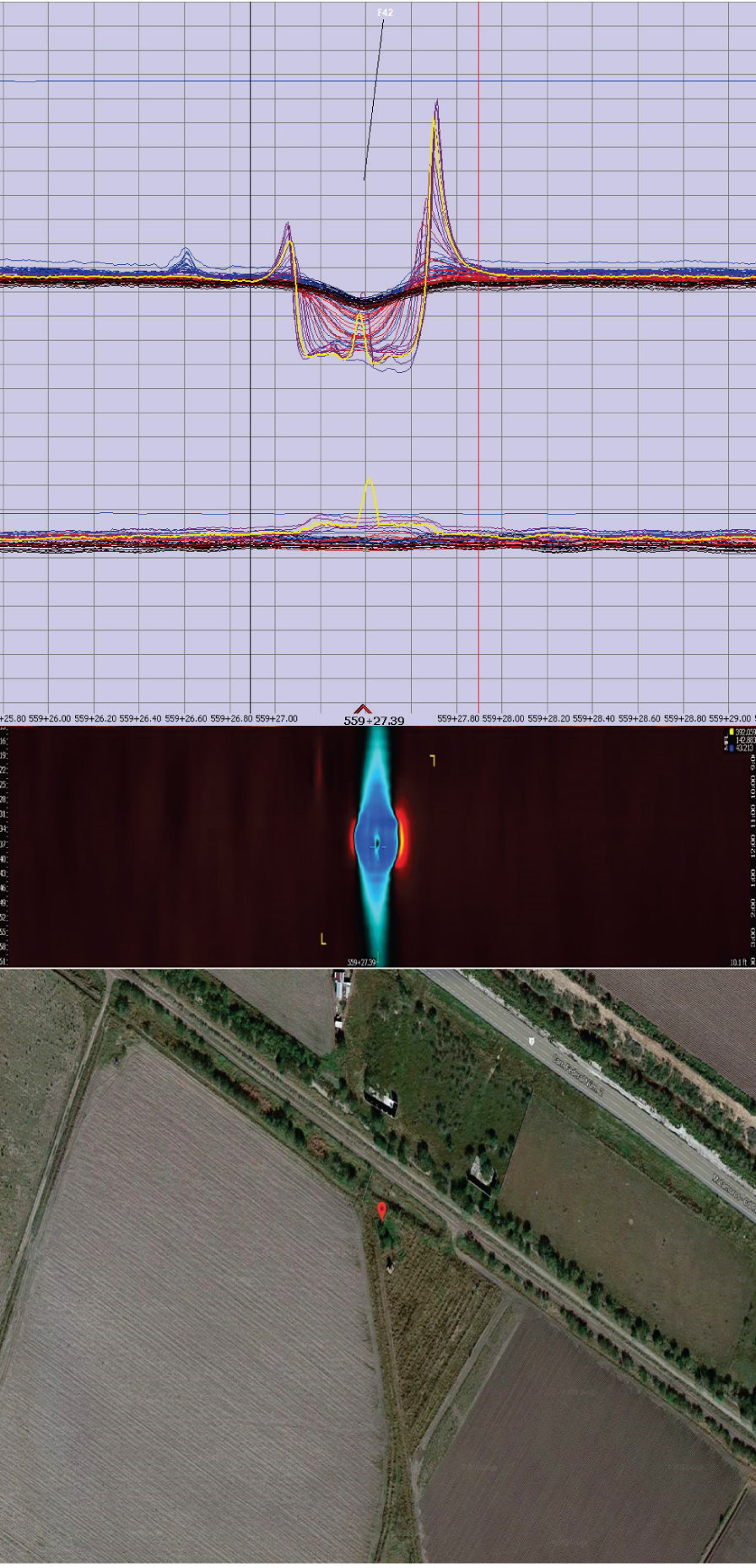

Data sets for conducting metal loss, deformation, and inertial surveys, along with internal/external discrimination and residual field data are taken in a single pass of the inspection tool. The DfL-UHR utilizes axial magnetic flux leakage data to provide an assessment of metal loss occurring within a pipeline.

Concurrent data set collection greatly simplifies the process of identifying features and anomaly types. Processing and analyzing the closely coupled data allows analysts to more readily recognize pipeline features and assess conditions. Any areas indicating geometry and/or metal loss features may now be simultaneously evaluated for deformation, strain, profile, and permeability variations.

The tool utilizes some of the most advanced design, data storage and packaging techniques presently available, as evidenced by the diverse data sets being taken and limited physical size and weight of the tools themselves, typically less in length and weight than most presently being offered.

Our MFL-DfL utilizes state-of-the-art Magnetic Flux Leakage technology to provide feature detection, such as:

- Automated sizing

- Sizing focused

- Sizing + Severity

- Sizing + Correlation

- Manual validation of any given number of indications

- Illegal hot tap locations

Need to reduce the speed? Our DSC 2.0 tool can be paired with both ILI & Cleaning tools.

Click here to go directly to the DSC 2 Page

Ensure and maintain the integrity of your pipeline assets frequently

Run our MFL-DfL as often as you desire and receive quick turn-around of your integrity data. Either way, we're here for you every step of the way!

MFL-DfL Features:

- Illegal Tapping

- Intuitive Maintenance

- Validate & Correlate

- Compact Configuration

- Run as Needed

- Cost Effective

- Robust Data Collection

- Run-to Run Corrosion Comparison

- Rapid Report Turnaround

Quick Results

As an excellent option for lines with short launch and/or receive line traps - The data can be quickly examined to determine new features/anomalies and reported to operators for prompt response - saving time and money.

Analysis Comparison

Analysis of the pipeline data can be conducted and compared to previous runs of the MFL detection tools.

A correlation report will identify any new tap features; new features that were not present in previous tool surveys are quickly recognized.

Prevent Catastrophes

By locating and addressing any potential integrity threats immediately, this will mitigate chances of a future catastrophic event.

With over 20 years of experience in the pipeline industry, Matt Peterson is known for his customer-first approach and dedication to getting the job done right the first time. As Enduro’s Business Development Director, Matt thrives on building strong relationships and working closely with clients to find the right products and services for their unique needs.

A proud Iowa native, Matt credits his strong work ethic to his upbringing—believing that hard work not only drives success but also delivers real value to customers. Outside the office, you’ll find him riding his Harley, staying active, or enjoying the outdoors with friends and family.

Favorite quote:

“Always do more than is required of you.” – George S. Patton Jr.

Matt Peterson

Business Development Director

Jeremy is a seasoned professional in the pipeline industry, bringing over 20 years of experience in pipeline operations, integrity management, and corrosion control. His extensive expertise in pipeline integrity and corrosion solutions makes him a trusted resource for operators seeking reliable and effective maintenance strategies.

As Enduro Pipeline Services' lead for sales in the Southeast U.S., Jeremy partners with customers to deliver tailored solutions that enhance performance and protect pipeline assets.

Outside of work, Jeremy enjoys spending quality time with family and friends, and is an avid outdoorsman who loves hunting and fishing.Outside of work, Jeremy enjoys spending time with his family and friends, and cn often be found hunting or fishing in the great outdoors.

Jeremy Secord

Senior Sales Representative

Brett Bowker

ILI Project Manager / Operations Supervisor

With 16 years at Enduro—and in the pipeline industry—Brett knows there’s always something new to learn and a challenge to tackle. He thrives on working with customers to ensure every inspection is a success and approaches his work with the mindset of Colossians 3:23: “Whatever you do, work at it with all your heart.” Off the clock, you’ll find Brett outdoors—camping, hiking, or chasing an Oklahoma sunset with his family.

HAVE QUESTIONS ABOUT YOUR ILI PROJECT? CONTACT OUR OPS TEAM

TRAVIS BELL

Operations Project Manager -EXT 111